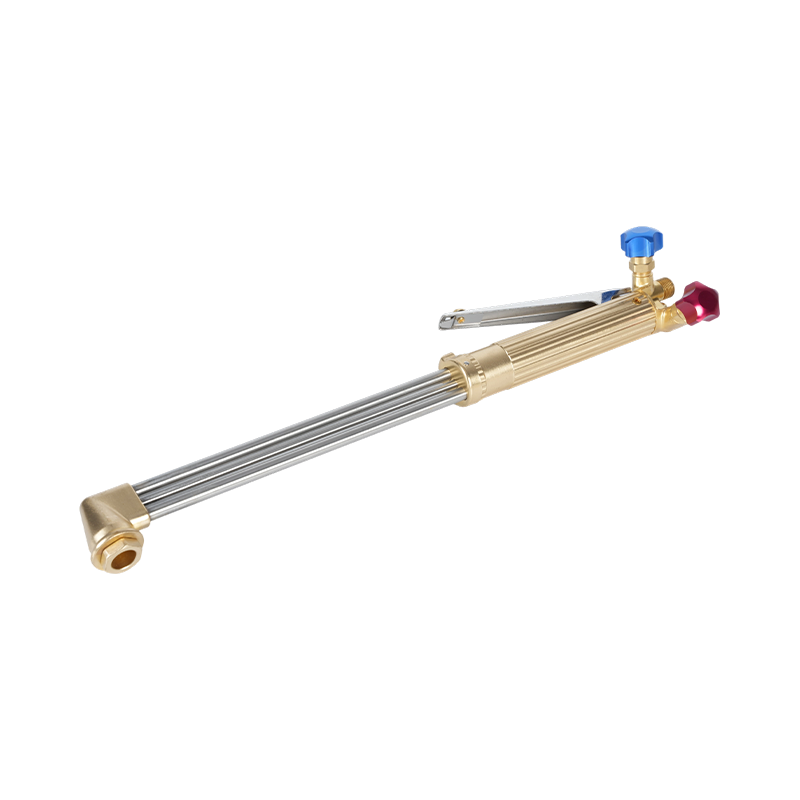

Hand Cutting Torch Material Selection

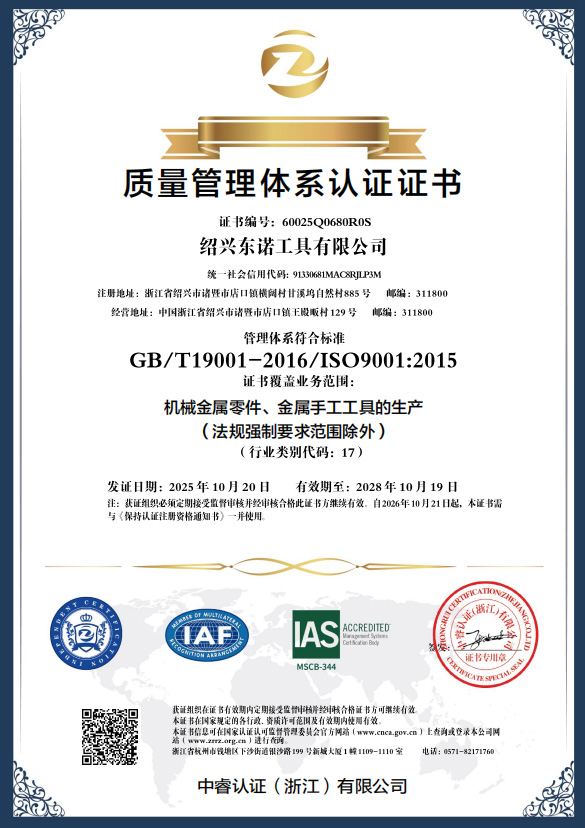

When choosing materials for hand cutting torches, the focus is not only on durability but also on heat resistance and corrosion prevention. Brass alloy is commonly used for the body and components due to its excellent thermal conductivity and resistance to sparks. At our workshop in Ningbo, we emphasize precision forging of brass components to ensure every cutting torch handle meets high-performance standards.

Steel and stainless steel parts are often employed for nozzle holders and tips to endure repeated heating cycles. Choosing the right combination of brass and steel can significantly extend the lifespan of your torch while maintaining smooth operation during continuous cutting tasks.

Ergonomics and Safety in Torch Handles

The ergonomics of a hand cutting torch can directly affect operator comfort and precision. Handles are often shaped to provide a natural grip, reducing fatigue during extended cutting sessions. Lightweight yet robust materials are preferred so the torch remains balanced without sacrificing durability.

Safety is enhanced through proper spacing of controls, clear visibility of adjustment knobs, and flame arrestor integration. In our experience at Ningbo Dongnuo, we integrate these elements during production to minimize the risk of flashbacks and ensure reliable performance on-site.

Nozzle and Tip Optimization

The design of cutting torch nozzles and tips has a major impact on cutting efficiency and flame stability. For example, tapered nozzles allow better oxygen flow and reduce turbulence, resulting in cleaner cuts. Matching the correct tip size with the metal thickness is critical; using an oversized tip can waste gas, while an undersized tip may cause uneven cutting.

We always recommend selecting tips that are specifically forged for your application. At our facility, we perform precision processing to maintain uniform bore diameters, which helps achieve consistent flame patterns and smooth metal separation.

Maintenance Practices for Longevity

Regular maintenance is essential to keep hand cutting torches operating at peak performance. Cleaning the nozzle tips with fine wire brushes, checking O-rings and seals, and inspecting hoses for cracks or leaks can prevent unexpected shutdowns and accidents. Using high-quality brass and forged components reduces wear and tear, ensuring longer service life.

I always advise our clients to schedule maintenance checks after heavy use. This approach not only preserves equipment but also keeps operational costs lower over time.

Torch Performance Comparison Table

| Torch Type |

Material |

Max Cutting Thickness |

Ergonomic Rating |

| Standard Hand Torch |

Brass + Steel |

25 mm |

High |

| Heavy-Duty Torch |

Forged Brass + Stainless Steel |

50 mm |

Medium |

| Precision Cutting Torch |

Brass Alloy |

15 mm |

Very High |

Advanced Usage Tips

For specialized applications like automotive sheet metal or stainless steel work, adjusting oxygen pressure and gas mixture is key. Slight variations in pressure can drastically improve cut quality and reduce slag formation. I personally guide our clients in Ningbo on optimal settings for different metals, ensuring they achieve professional-grade results consistently.

In addition, pairing hand cutting torches with flashback arrestors and precision regulators ensures both safety and cutting accuracy. This combination is especially important in industrial environments where high efficiency and operator protection are required.

Troubleshooting Common Issues

Common problems such as uneven cuts, flame flickering, or nozzle clogging can often be traced back to maintenance lapses or improper tip selection. Cleaning the nozzle and adjusting the gas ratio usually resolves these issues. In our production line, we perform strict quality control and recommend end-users to replicate similar inspections periodically.

Being proactive about these minor adjustments prevents costly downtime and extends the operational life of the torch, which is why I always emphasize practical hands-on care in addition to product quality.