Introduction to Heating Torches

Heating torches are versatile tools used in various industries for tasks such as soldering, brazing, and metalworking. They generate high-intensity flames, making them essential for tasks requiring precise heat application. However, like any piece of equipment that operates at high temperatures, heating torches require proper cleaning and maintenance to ensure they function safely and efficiently. Neglecting these tasks can lead to poor performance, reduced lifespan, and safety hazards.

Importance of Regular Maintenance

Proper maintenance of heating torches ensures their longevity and optimal performance. Regular upkeep prevents potential malfunctions and reduces the risk of dangerous situations. It also helps maintain the efficiency of the flame, ensuring consistent results in every application.

Key Steps for Cleaning Heating Torches

1. Turn Off the Torch and Allow It to Cool

Before cleaning a heating torch, it is essential to turn it off and allow it to cool completely. Handling the torch while it's still hot can cause burns or other injuries. Once it cools, check for any accumulated residue or carbon build-up, which can affect the performance of the torch.

2. Inspect and Clean the Torch Tip

The torch tip is one of the most crucial components of the heating torch. Over time, the tip can accumulate carbon deposits, which may obstruct the flow of gas and affect the size and quality of the flame. Cleaning the tip regularly can prevent clogs and ensure that the flame remains consistent and efficient.

- Use a soft brush or compressed air to remove any debris or residue from the torch tip.

- For stubborn build-up, a wire brush or torch cleaning tool may be used carefully to avoid damaging the tip.

- Check for any wear or damage to the tip. If it's worn out, consider replacing it to maintain efficient operation.

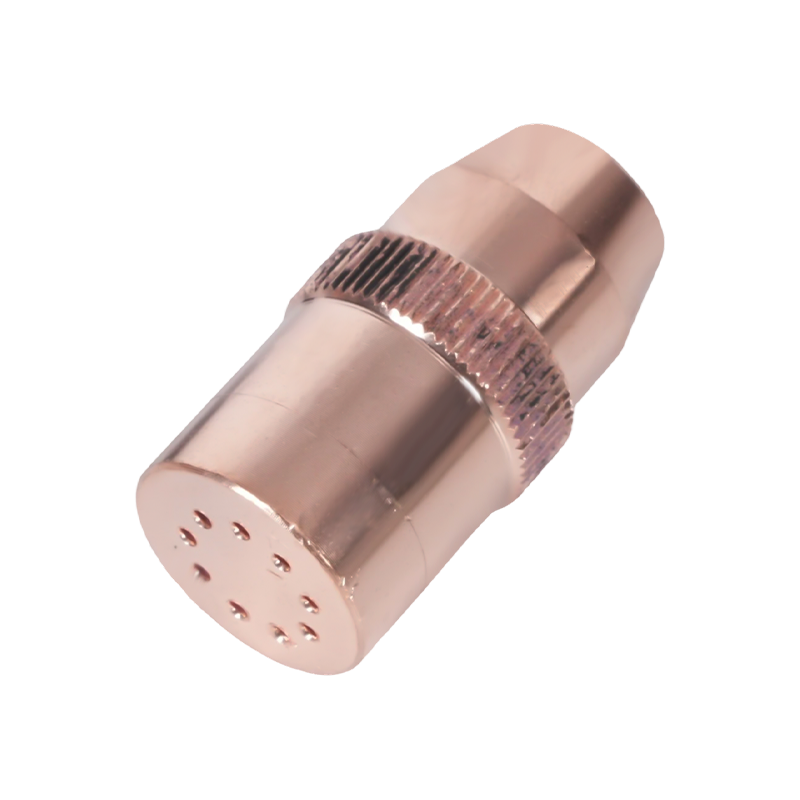

3. Clean the Nozzle

The nozzle is responsible for shaping the flame, and its cleanliness directly affects the torch's performance. Dirt, soot, or metal deposits can clog the nozzle, leading to uneven or weak flames. Regular cleaning helps maintain an even and controlled heat output.

- Remove the nozzle from the torch and inspect for any build-up or clogs.

- Clean the nozzle using a soft brush, compressed air, or a cleaning tool designed for the purpose.

- Avoid using abrasive materials, as they can scratch and damage the nozzle surface.

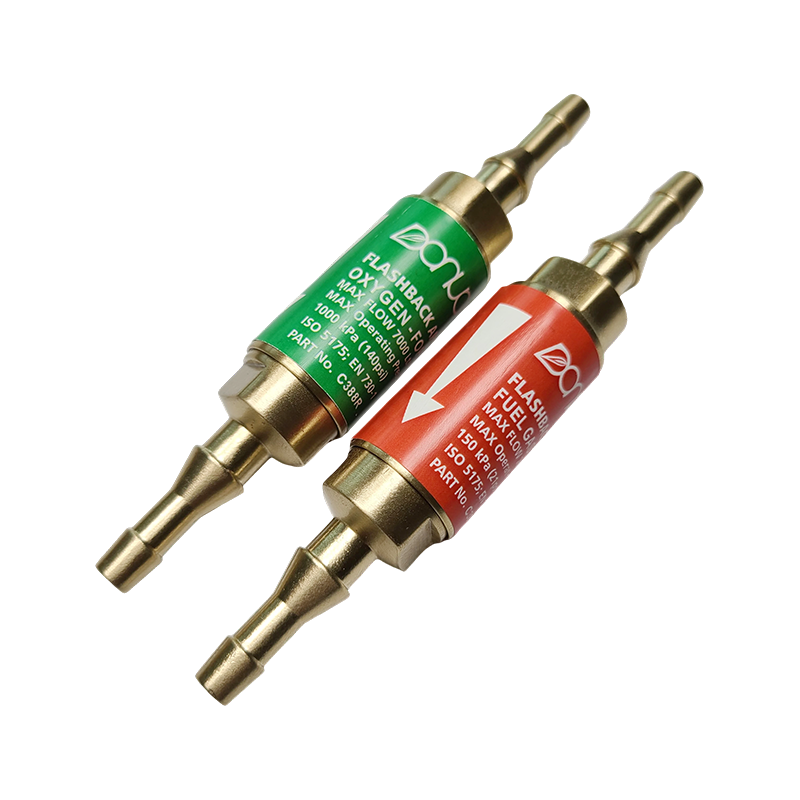

4. Check and Clean the Gas Supply Line

The gas supply line is a vital part of the heating torch system. If it becomes clogged or contaminated, it can restrict gas flow, resulting in poor flame quality. Ensuring the gas supply line is clear and free of blockages is crucial for maintaining consistent performance.

- Inspect the gas line for any visible signs of damage or wear.

- Use compressed air to blow out any dirt or debris that may be obstructing the line.

- Check the connections for leaks. If any leaks are detected, tighten or replace the fittings as necessary.

Proper Maintenance Tips for Longevity

1. Regular Inspection and Lubrication

Regular inspection of all parts is necessary to spot any potential issues early. Lubricating the moving parts of the torch can help prevent friction and wear, ensuring smoother operation and extending the torch's lifespan. Use the manufacturer-recommended lubricants and apply them sparingly to avoid excess build-up.

2. Keep the Torch Stored Properly

Proper storage is essential to ensure the longevity of your heating torch. Store the torch in a dry, cool place, and ensure it is kept in an upright position to prevent damage to its parts. Using a protective cover or case can help shield it from dust, dirt, and moisture, further prolonging its life.

3. Monitor Gas Pressure

Maintaining the correct gas pressure is vital for optimal torch performance. Low pressure can result in a weak flame, while high pressure can cause excessive wear and even dangerous situations. Regularly check and adjust the gas pressure according to the manufacturer's guidelines.

4. Replace Worn-Out Parts

Over time, certain components of the heating torch, such as the nozzle or tip, may wear out due to frequent use. It’s important to replace these parts promptly to maintain the torch’s efficiency. Always use parts that are compatible with your specific torch model to ensure optimal performance.

Conclusion

Regular cleaning and maintenance of heating torches are essential practices for ensuring their proper functioning and longevity. By following the steps outlined in this article—such as inspecting and cleaning the torch tip, nozzle, and gas supply line, as well as performing regular checks on gas pressure and lubrication—you can keep your torch in excellent condition for consistent, high-quality results in your work. Proper maintenance not only extends the life of the tool but also improves safety and efficiency, making it a crucial aspect of your heating torch's care routine.