Understanding Flashback Arrestors

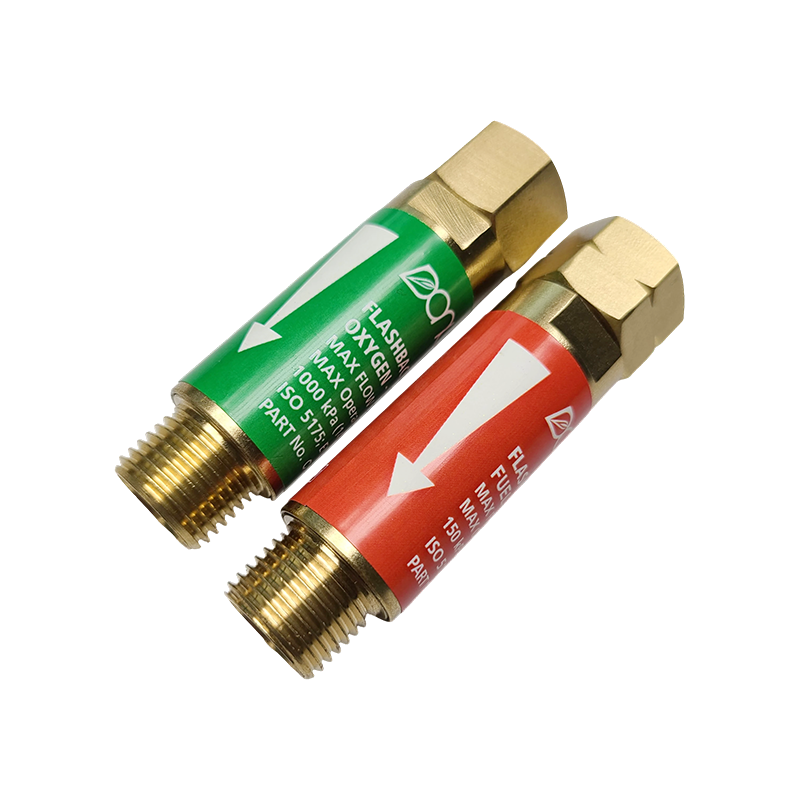

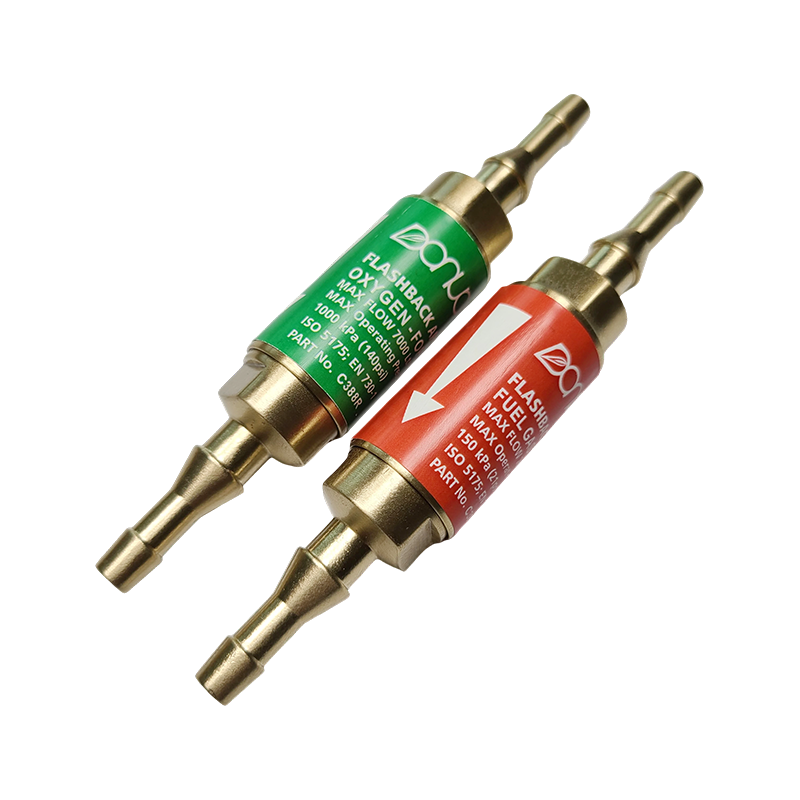

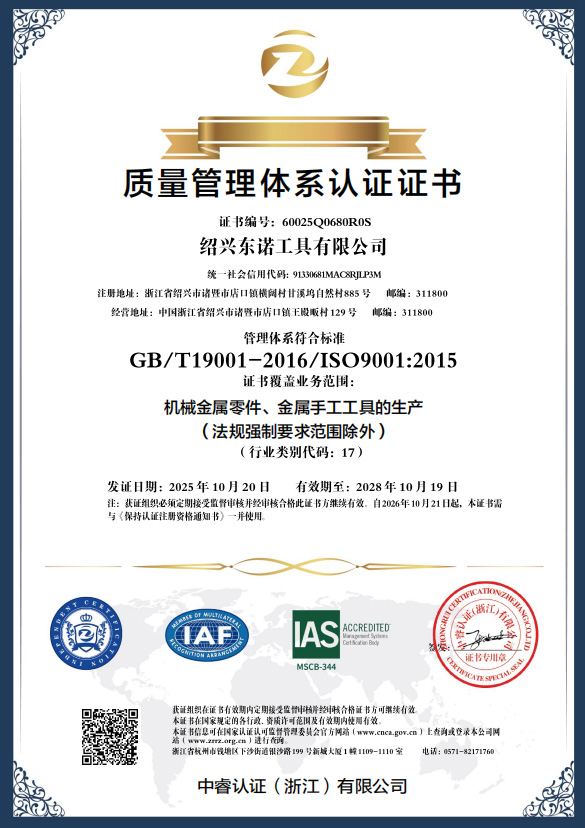

Flashback arrestors are critical safety devices used in oxy-fuel welding and cutting systems to prevent flames from traveling back into gas supply lines. At our factory in Ningbo, we produce high-quality flashback arrestors that meet strict safety standards, ensuring both industrial and personal safety.

Key Components of Flashback Arrestors

A typical flashback arrestor consists of several essential elements, each designed to prevent specific hazards:

- Check Valve: Prevents reverse gas flow that can lead to dangerous mixing of gases.

- Flame Arrestor: A metal mesh that extinguishes a flame before it can reach the regulator or cylinder.

- Thermal Cut-Off: Automatically shuts off gas flow if the device detects excessive heat from a flashback.

Our precision machining capabilities in brass alloy allow us to produce these components with tight tolerances, ensuring reliability under continuous use.

Installation Best Practices

Proper installation of flashback arrestors is crucial. Here are practical tips based on industry experience:

- Always install the flashback arrestor as close to the torch or regulator as possible.

- Check the flow direction indicated on the device; incorrect orientation can render it ineffective.

- Regularly inspect for debris or damage, especially after heavy-duty cutting operations.

At our facility, every flashback arrestor undergoes strict quality control to ensure that installation leads to optimal performance and maximum safety.

Maintenance and Inspection Guidelines

Routine maintenance extends the life of flashback arrestors and prevents accidents. Key steps include:

- Cleaning: Periodically clean the flame arrestor mesh to avoid clogging from soot or debris.

- Leak Testing: Use a soapy water solution to detect any leaks at connections.

- Replacement: Replace the unit immediately if there is any sign of damage or if the flow rate is significantly reduced.

Our products are designed for easy maintenance, saving you time and reducing downtime during critical operations.

Comparing Different Types of Flashback Arrestors

Flashback arrestors come in various forms, each suitable for specific applications:

| Type |

Primary Function |

Best Use |

| Torch-End |

Stops flashback at the torch |

Welding and cutting operations with high mobility |

| Regulator-End |

Protects gas supply from reverse flow |

Permanent installations or high-pressure cylinders |

| Dual-End |

Provides maximum protection on both ends |

Critical safety applications where risk of flashback is high |

In our production, we offer all these types, allowing customers to choose the right protection level for their specific operations.

Integrating Flashback Arrestors with Other Equipment

To maximize safety, flashback arrestors should be integrated with compatible regulators, hoses, and cutting torches. Our comprehensive product lineup allows seamless integration, ensuring stable gas flow and robust safety. Remember:

- Always match the pressure rating of the flashback arrestor with the gas regulator.

- Use hoses certified for the specific gas type to prevent degradation over time.

- Keep the system free from unnecessary bends or kinks to maintain proper flow.

We take pride in supplying high-quality accessories that work perfectly with our flashback arrestors for a safe and efficient welding experience.