Understanding Heating Tips for Precision Work

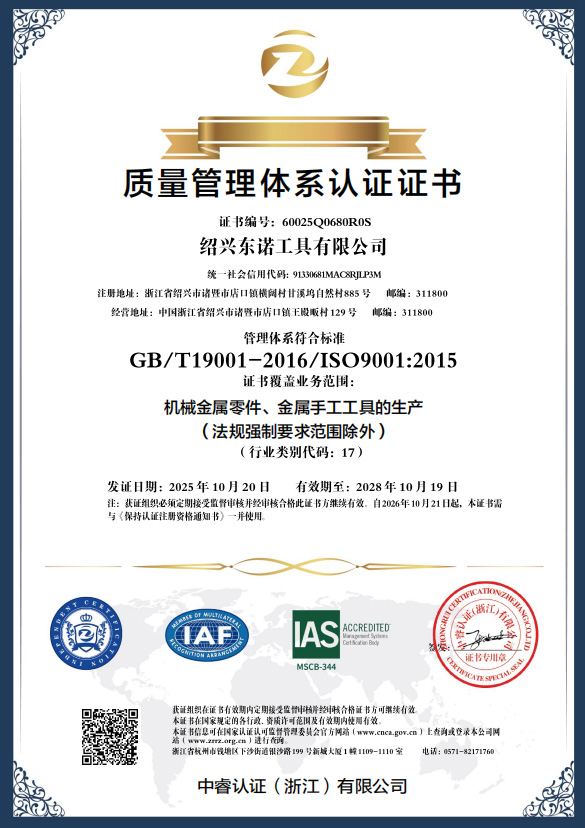

Heating tips are more than just attachments for welding or cutting tools—they directly influence the efficiency and quality of the work. Using the right tip ensures uniform heat distribution, reduces fuel consumption, and prolongs the life of your equipment. In my experience at Ningbo Dongnuo, selecting the correct heating tip can drastically improve your workflow, especially in industrial applications.

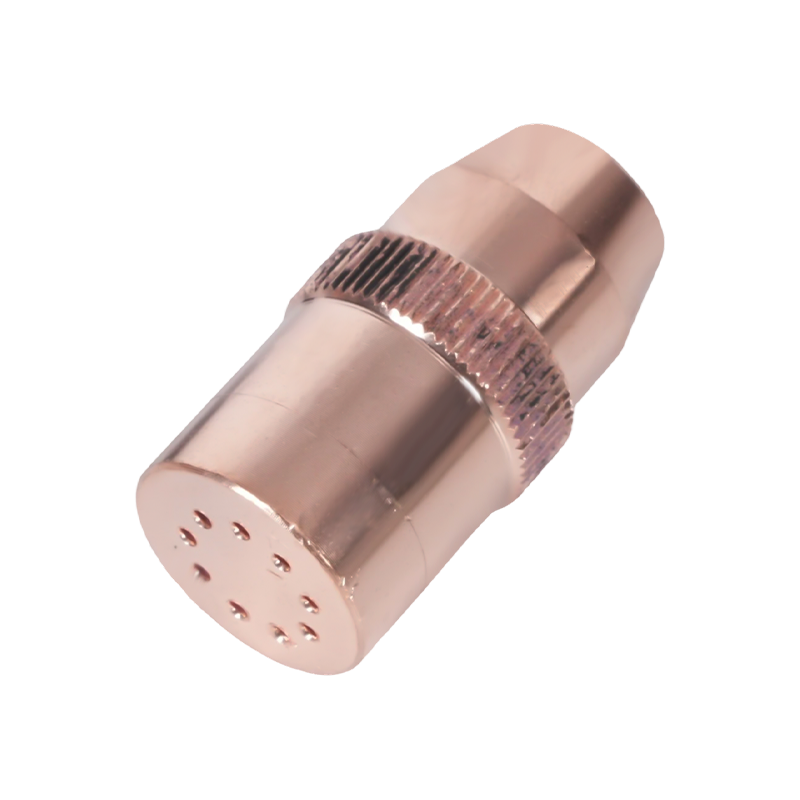

Material Considerations for Heating Tips

Different materials require different heating strategies. Copper alloy tips are excellent for high thermal conductivity, while brass alloy tips provide durability for heavy-duty operations. I often recommend our precision-forged brass alloy tips for customers who need consistent performance and longevity.

Tip Shapes and Their Applications

- Conical tips – best for focused heating on small surfaces.

- Flat tips – ideal for spreading heat evenly over larger areas.

- Specialty shaped tips – used in custom industrial processes where precise heat control is critical.

Gas Type and Pressure Matching

Proper gas selection and pressure adjustment are crucial for optimal tip performance. Propane, acetylene, and natural gas each require different tip configurations to achieve maximum efficiency. At our workshop, I ensure every tip is tested under specific gas pressures to guarantee consistent flame stability.

Maintenance Tips for Longevity

Regular maintenance can extend the lifespan of heating tips significantly. Here are some practical tips I follow personally:

- Clean the tip after each use to remove carbon deposits.

- Inspect the orifice for wear or damage before starting critical jobs.

- Store tips in a dry environment to prevent oxidation and corrosion.

Optimizing Work Efficiency

Using the right heating tip can significantly reduce job time. For instance, flat tips can cover large surfaces quickly, while conical tips allow for delicate adjustments without overheating the surrounding material. Personally, I’ve noticed that investing in high-quality tips from our Ningbo Dongnuo production line saves time and reduces operational costs in the long run.

Practical Tip Selection Table

| Tip Type |

Recommended Use |

Best Material |

| Conical |

Precision heating, small welds |

Copper alloy |

| Flat |

Even heating over large areas |

Brass alloy |

| Specialty |

Custom industrial processes |

Precision-forged brass |

Enhancing Safety During Heating Operations

Proper tip selection also improves safety. A tip that distributes heat evenly reduces the risk of accidental burns or material warping. In our factory, I always emphasize pairing high-quality tips with reliable gas regulators and flowmeters to ensure both efficiency and safety during welding or cutting operations.