Selecting the Right Cutting Torch Kit for Your Work

Choosing a cutting torch kit isn’t just about picking the most expensive model. Understanding the types of torches, tips, and gas compatibility is crucial. For example, propane cutting torches are ideal for small-scale metal cutting, while acetylene torches provide higher heat for industrial steel applications. At Ningbo Dongnuo, we focus on precision-engineered cutting guns that make even complex metalwork easier.

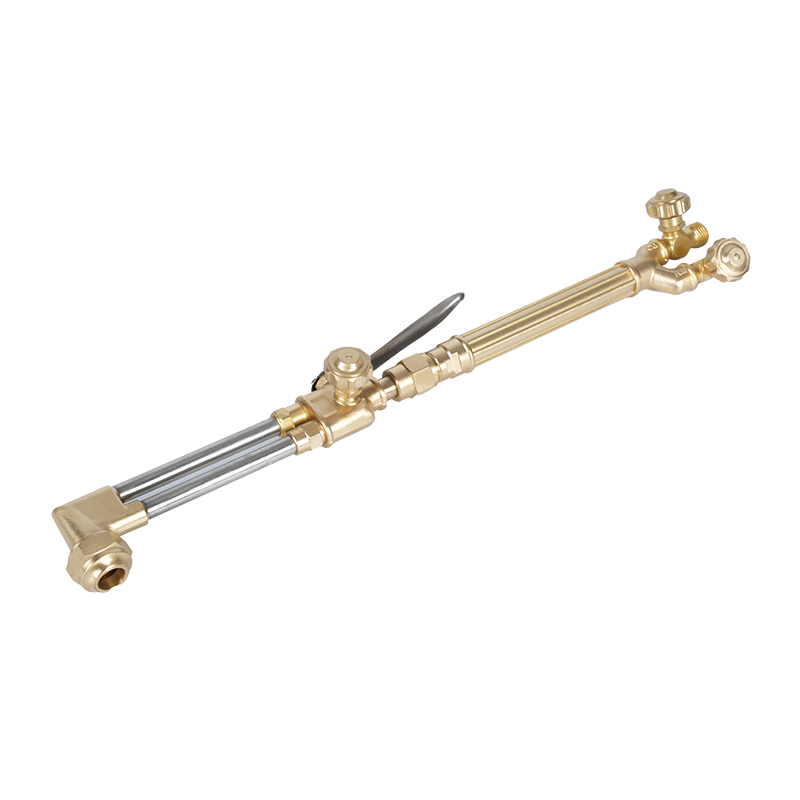

Torch Handles and Comfort

The handle design affects operator fatigue and precision. Ergonomic handles with well-placed valves reduce hand strain during long operations. I always recommend testing the grip and weight balance before committing to a kit, and our cutting torch handles are crafted for comfort without compromising durability.

Nozzle Selection and Metal Thickness

Nozzles control flame shape and cutting speed. Choosing the correct nozzle diameter is vital for clean cuts:

- Small diameter tips: precise cuts on thin sheets.

- Medium diameter tips: versatile, suitable for general fabrication.

- Large diameter tips: heavy-duty cutting on thick steel plates.

We offer a range of nozzles compatible with different torch models, ensuring every operator can match performance with task requirements.

Gas Pressure and Flow Control

Maintaining the correct gas pressure is essential for efficiency and safety. Too low, and the cut is weak; too high, and the metal can warp. Our gas pressure reducers and flowmeters are designed for stability and accuracy, giving you consistent performance during critical operations.

Mixing Gases for Optimal Results

Some applications require precise gas mixtures. For instance, combining propane with oxygen can increase cutting efficiency on medium-thick steel. Understanding flow rates and pressures is key. At Ningbo Dongnuo, we provide detailed flowmeter calibration guidance to help you get the perfect mix every time.

Proper maintenance extends the life of your equipment. Regular inspection of hoses, connections, and nozzles prevents leaks and ensures consistent flame quality. I personally encourage cleaning the tips with appropriate tools after every use to maintain peak performance.

Storage Tips

Storing torches and accessories in a dry, ventilated area prevents corrosion and damage. Using protective covers for nozzles and handles also helps maintain their shape and functionality. Our kits come with compact storage solutions, which I find particularly handy for workshop organization.

Troubleshooting Common Issues

Frequent issues include uneven cuts, irregular flames, and slow metal penetration. Here’s a practical table to quickly identify causes and solutions:

| Issue |

Possible Cause |

Recommended Action |

| Uneven flame |

Clogged nozzle |

Clean or replace nozzle |

| Slow cutting |

Low gas pressure |

Adjust pressure with regulator |

| Warped metal |

Excessive heat or slow movement |

Move torch steadily, adjust flame size |