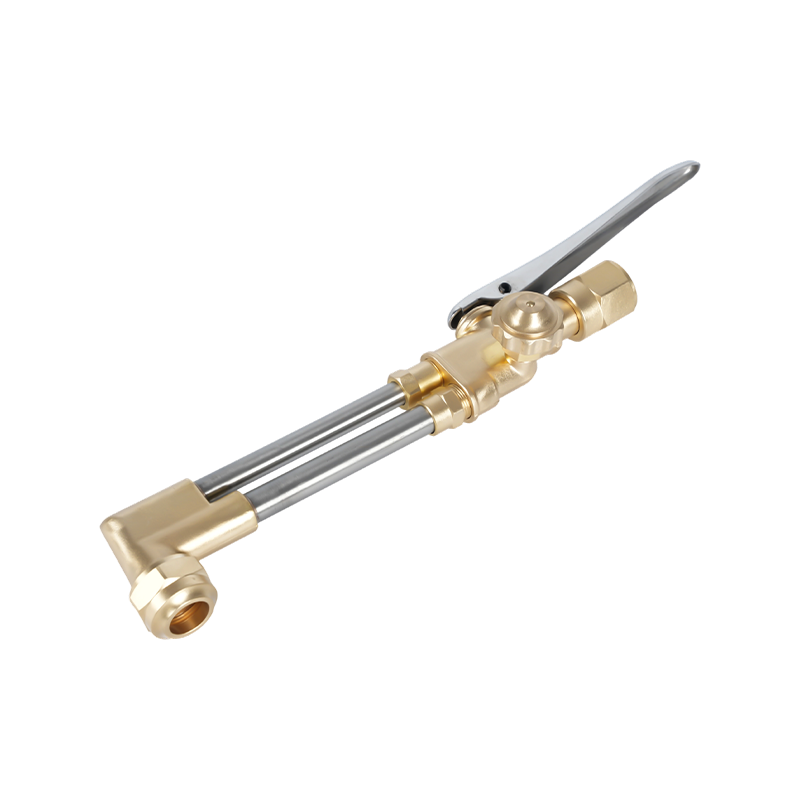

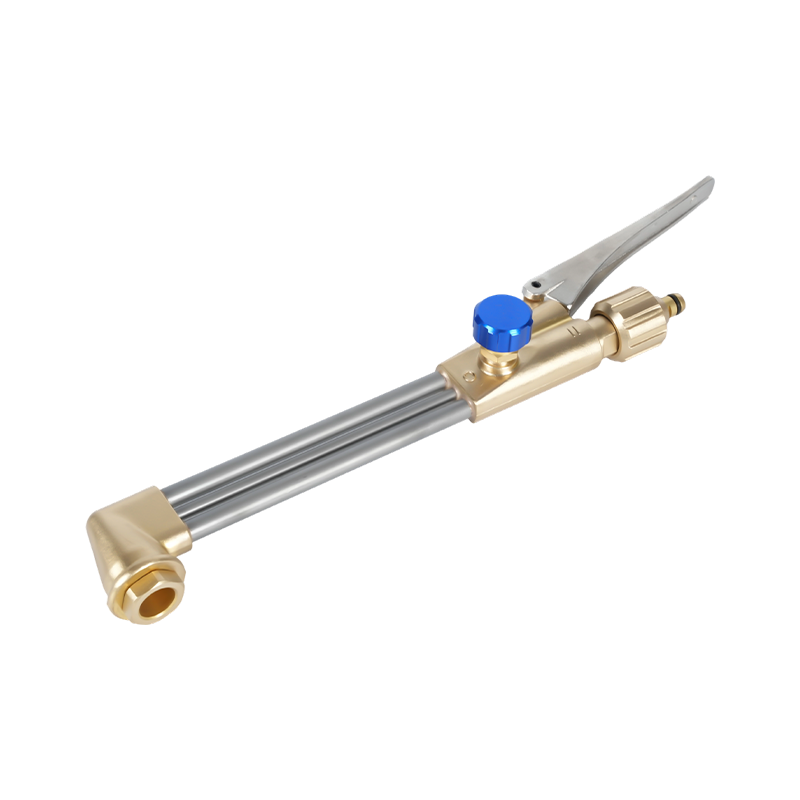

Cutting Attachment Materials and Their Applications

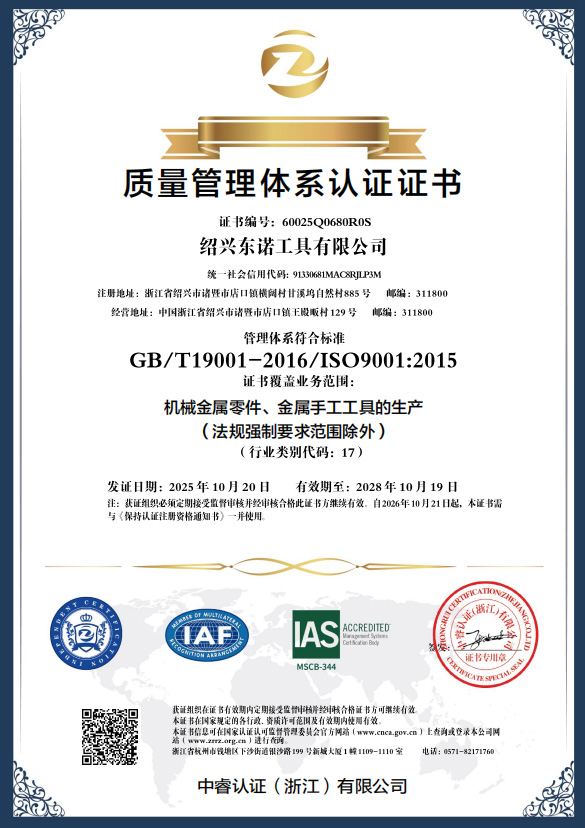

Cutting attachments are not just add-ons—they directly influence the efficiency and precision of your cutting operations. In our experience at Ningbo Dongnuo, using high-quality brass alloy and precision-forged components ensures consistent performance under high temperatures and repeated use. Brass provides excellent heat resistance and durability, making it the preferred choice for most industrial cutting applications.

Common Materials Used

- Brass Alloy: Offers corrosion resistance, high thermal conductivity, and long service life.

- Stainless Steel: Used for components that require higher structural strength, especially in heavy-duty cutting tasks.

- Copper: Sometimes used for specific tips where precise thermal transfer is critical.

- Aluminum: Lightweight components for portable or hand-held cutting torches.

Precision in Cutting Attachment Design

The design of a cutting attachment affects both the flame stability and the cut quality. At our factory, we emphasize precision forging and machining for all cutting gun components. Proper alignment of the torch head and oxygen/fuel channels ensures cleaner cuts and reduces metal waste.

Key Design Features

- Interchangeable Tips: Allow different cutting sizes without replacing the entire torch.

- Ergonomic Handles: Reduce fatigue during long cutting operations.

- Optimized Flow Channels: Ensure even distribution of fuel and oxygen for consistent flame performance.

- Durable Couplings: Resistant to high temperatures and repeated assembly/disassembly.

Maintenance Tips for Cutting Attachments

Even the best cutting attachments require proper maintenance to sustain their performance. From my perspective working with these tools daily, simple practices can extend the lifespan and efficiency of your attachments.

Practical Maintenance Practices

- Regular Cleaning: Remove metal slag and debris from torch tips to prevent flame instability.

- Check for Wear: Inspect the cutting edge and fittings for deformation or erosion.

- Lubricate Moving Parts: Some attachments have mechanical joints that benefit from occasional lubrication.

- Proper Storage: Keep attachments in dry, dust-free environments to prevent corrosion.

Selecting the Right Cutting Attachment for Your Task

Choosing the correct cutting attachment is crucial for efficiency and safety. Based on our production experience, factors like material thickness, type of metal, and cutting environment should guide your selection.

Comparison Table of Cutting Attachments

| Attachment Type |

Ideal Metal Thickness |

Recommended Fuel |

Special Features |

| Standard Cutting Tip |

5-20mm |

Acetylene |

High precision for general cutting |

| Heavy-Duty Tip |

20-50mm |

Propane or Acetylene |

Reinforced for thick metal cuts |

| Fine Cutting Tip |

1-5mm |

Acetylene |

Precision work for thin metals |

At Ningbo Dongnuo, we integrate these insights into our manufacturing process, ensuring every cutting attachment is crafted for durability and performance. When you choose our products, you're not just buying tools—you’re investing in reliability and efficiency on every cut.