Metal Cutting in Fabrication Workshops

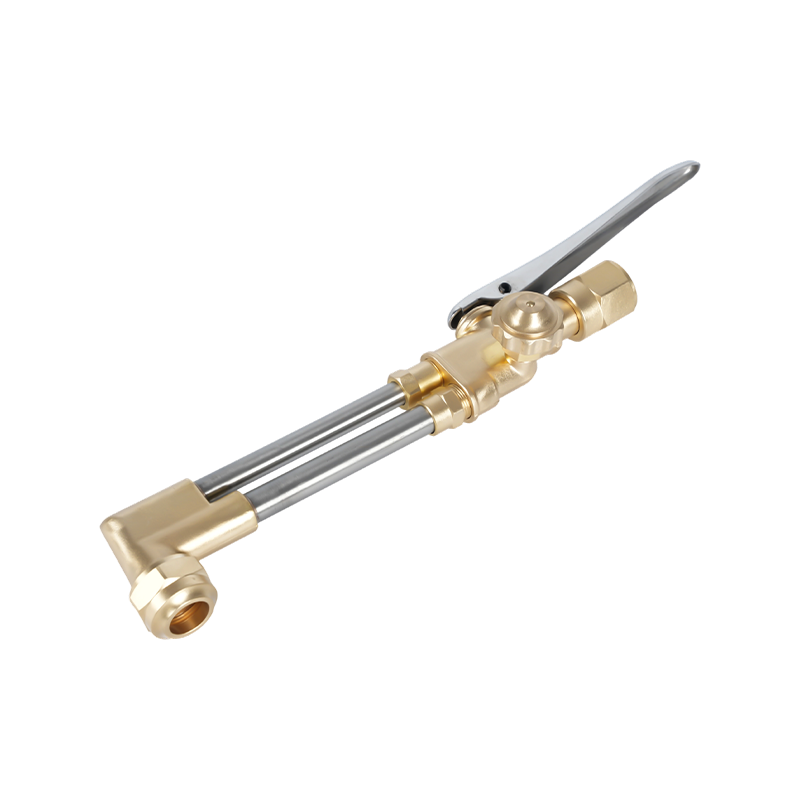

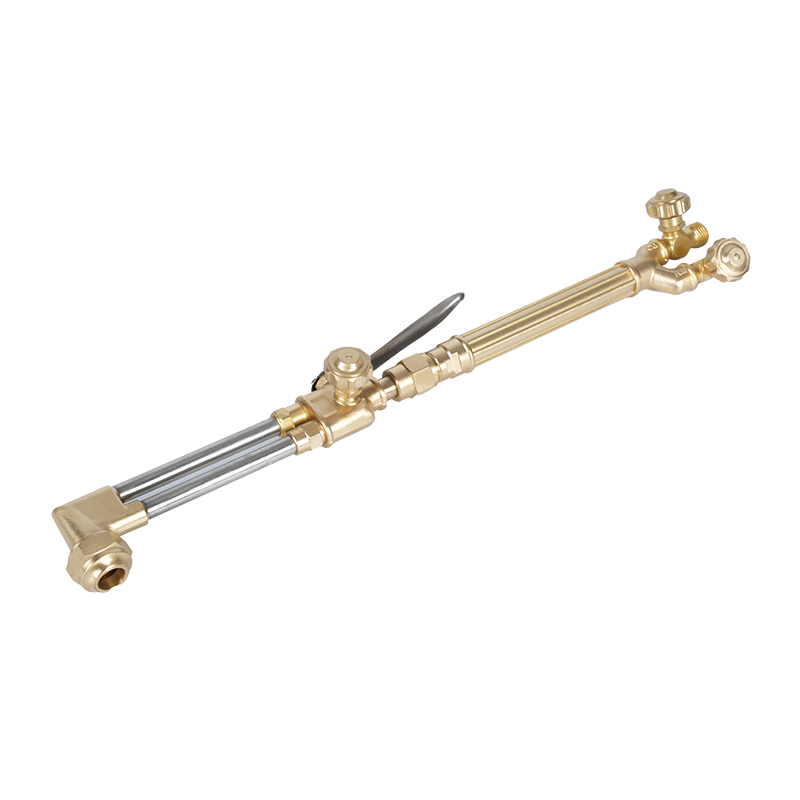

Cutting Torch Kits are widely used in metal fabrication workshops where precise and efficient cutting of steel and other metals is required. These kits, typically operating with oxy-fuel gas combinations, allow operators to cut through thick metal plates that are difficult to process with mechanical tools. Fabricators rely on torch kits to prepare raw materials before welding, bending, or machining.

In small and medium workshops, Cutting Torch Kits offer flexibility. They do not require complex electrical setups and can be moved easily between workstations. This makes them suitable for custom fabrication tasks, short production runs, and repair-based work where adaptability is important.

Common Fabrication Tasks

- Cutting steel plates to size before welding

- Trimming excess metal from fabricated assemblies

- Creating openings or slots in metal structures

Construction and Structural Steel Work

In construction projects, Cutting Torch Kits play a key role in handling structural steel components. Beams, columns, and metal frames often need on-site adjustments due to design changes or measurement corrections. Torch kits allow construction teams to cut and modify steel elements directly at the job site without moving them back to a workshop.

Their ability to cut through thick and reinforced steel makes them especially useful in large-scale infrastructure projects such as bridges, factories, and high-rise buildings. The speed of torch cutting helps reduce downtime and keeps projects on schedule.

On-Site Advantages

- No dependency on high-power electrical sources

- Effective for thick structural steel sections

- Suitable for outdoor and temporary work sites

Automotive and Machinery Repair

Cutting Torch Kits are commonly used in automotive repair shops and machinery maintenance facilities. When bolts, brackets, or metal panels are seized, corroded, or damaged, torch cutting offers a fast solution. Instead of disassembling entire systems, technicians can remove problematic parts directly.

In heavy machinery repair, torch kits help technicians cut thick metal housings or frames during part replacement. This reduces labor time and allows repair teams to restore equipment functionality more quickly.

Shipbuilding and Marine Maintenance

The shipbuilding industry relies heavily on Cutting Torch Kits for both construction and maintenance tasks. Large steel plates used in hulls and decks require precise cutting during assembly. Torch kits provide the necessary power to cut marine-grade steel efficiently.

During maintenance and repair, torch kits are used to remove damaged sections caused by corrosion or impact. Their portability allows use in shipyards, dry docks, and even confined spaces within vessels.

Typical Marine Applications

- Cutting hull plates for replacement

- Removing corroded structural sections

- Modifying steel components during refits

Scrap Metal Processing and Recycling

Scrap yards and recycling facilities use Cutting Torch Kits to break down large metal items into manageable sizes. Old machinery, vehicles, and industrial equipment often contain thick steel components that cannot be processed whole. Torch cutting allows workers to separate and reduce these materials efficiently.

By cutting scrap metal into standardized sizes, recycling facilities can improve handling, transportation, and melting efficiency. This directly supports cost control and operational productivity.

Industrial Maintenance and Plant Shutdowns

In factories and processing plants, Cutting Torch Kits are essential tools during maintenance shutdowns. Old pipelines, tanks, and steel frameworks often need to be removed or modified. Torch cutting enables maintenance teams to dismantle outdated systems quickly.

Because shutdown periods are time-sensitive, the speed and reliability of torch kits make them a practical choice. They allow maintenance crews to complete complex cutting tasks within limited time frames.

Comparison of Common Applications

| Industry | Main Use | Typical Material |

| Fabrication | Cutting raw metal plates | Carbon steel |

| Construction | On-site steel adjustment | Structural steel |

| Recycling | Scrap size reduction | Mixed metals |

Training, Education, and Skill Development

Technical schools and vocational training centers use Cutting Torch Kits to teach metal cutting fundamentals. Students learn how heat, oxygen flow, and cutting angles affect results. These skills form a foundation for careers in welding, fabrication, and industrial maintenance.

Because torch kits clearly demonstrate cutting principles, they remain relevant teaching tools even as automated cutting technologies advance.

Why Cutting Torch Kits Remain Practical

Despite the availability of advanced cutting machines, Cutting Torch Kits remain in demand due to their reliability and versatility. They perform well in environments where power supply is limited or where materials vary in thickness and condition. Their relatively low operating cost also makes them accessible for many businesses.

For industries that value flexibility, portability, and proven performance, Cutting Torch Kits continue to serve as essential tools across a wide range of practical applications.