Introduction to Flashback Arrestors

Flashback arrestors are essential safety devices used in welding and cutting operations involving flammable gases. They prevent the dangerous reverse flow of gas and the propagation of flames back into gas supply lines, which can cause fires, explosions, and serious injuries.

Typically installed between the gas source and the torch, flashback arrestors combine mechanical valves, flame-retardant filters, and non-return devices to halt flashbacks instantly. Their integration into welding systems is a critical step in maintaining workplace safety and compliance with industry standards.

How Flashback Arrestors Work

Flashback arrestors function by detecting abnormal flame or pressure conditions in the gas line. When a flashback occurs, the device closes its internal valves and traps the flame, preventing it from traveling back to the gas cylinder. High-temperature flame screens or sintered metal filters dissipate heat and extinguish the flame.

Additionally, non-return valves prevent reverse gas flow, ensuring that oxygen, acetylene, or other fuel gases do not mix in dangerous proportions within supply lines. This dual mechanism—flame arresting and backflow prevention—makes flashback arrestors highly effective in mitigating welding hazards.

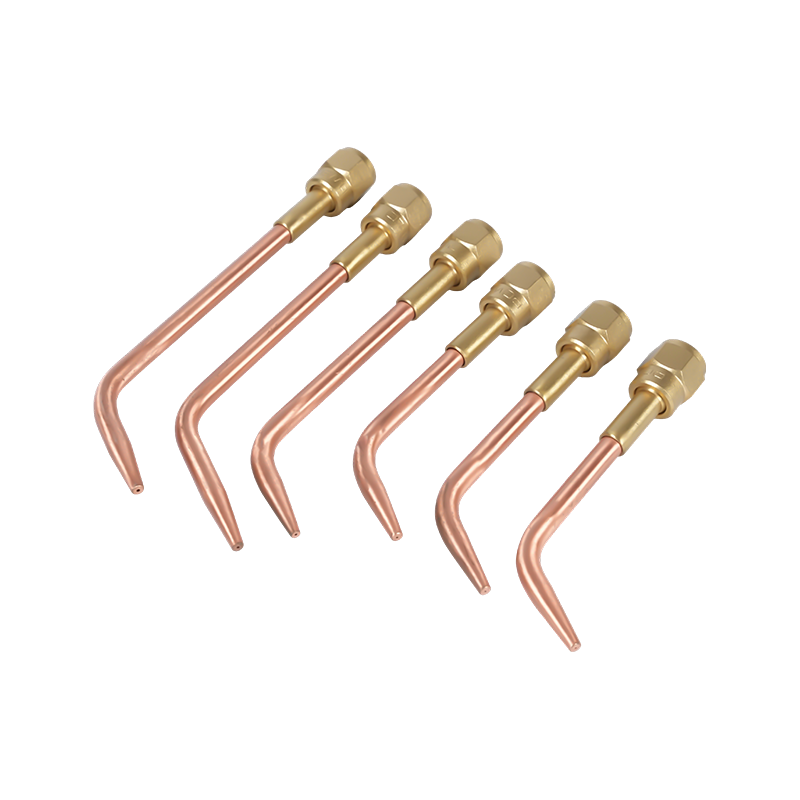

Types of Flashback Arrestors

There are several types of flashback arrestors, designed to address different safety concerns:

- Fuel Gas Arrestors: Installed on acetylene, propane, or hydrogen lines to prevent backflow of fuel gas into oxygen cylinders.

- Oxygen Arrestors: Protect oxygen supply lines from flashback and contamination by other gases.

- Combination Arrestors: Provide both fuel gas and oxygen protection in a single unit, often used in portable welding setups.

Key Safety Benefits in Welding Operations

Flashback arrestors enhance workplace safety by addressing multiple hazards associated with gas welding:

- Prevent Explosions: Stop flame propagation into gas cylinders, reducing risk of catastrophic accidents.

- Protect Equipment: Prevent damage to regulators, hoses, and torches caused by flashbacks.

- Ensure Worker Safety: Reduce the risk of burns, fires, and inhalation hazards for welding personnel.

- Maintain Gas Purity: Non-return valves prevent dangerous gas mixing that could compromise welding quality or safety.

Regulatory Compliance and Standards

Using flashback arrestors helps companies comply with international safety standards, such as ISO 5175, EN 730, and OSHA regulations. These standards specify requirements for flame arresting, backflow prevention, and pressure handling to ensure consistent safety in industrial gas operations.

Regular inspection, testing, and maintenance of flashback arrestors are essential for regulatory compliance. Most devices include visual indicators to show valve function, and periodic replacement is recommended to maintain optimal safety performance.

Installation Guidelines for Optimal Safety

Proper installation of flashback arrestors is crucial for effectiveness. They should be mounted as close as possible to the torch and between regulators and hoses. Correct orientation, according to manufacturer instructions, ensures that the non-return valve and flame arresting components function correctly.

It is also important to match arrestors with the type of gas and flow rate. Using a fuel gas arrestor on an oxygen line or an undersized device can compromise protection, leading to potential hazards. Clear labeling and training for operators further enhance safety.

Maintenance and Testing

Routine maintenance ensures flashback arrestors continue to perform reliably. Maintenance typically includes:

- Cleaning or replacing flame arrestor filters to prevent blockage.

- Checking non-return valve function for proper closure and seal integrity.

- Inspecting for wear, corrosion, or physical damage.

Regular testing with manufacturer-recommended methods ensures continued compliance with safety standards and prevents potential accidents caused by device failure.

Comparison with Systems Without Flashback Arrestors

| Feature | With Flashback Arrestor | Without Flashback Arrestor |

| Flame Propagation | Prevented | Possible |

| Backflow Risk | Eliminated | High |

| Equipment Damage | Minimal | Likely |

| Worker Safety | High | Reduced |

Conclusion: Critical Role in Welding Safety

Flashback arrestors are indispensable for ensuring workplace safety in welding operations. By preventing flame propagation, controlling gas backflow, and protecting equipment, they significantly reduce the risk of fire, explosions, and injuries.

Proper selection, installation, and maintenance of flashback arrestors enable industrial facilities to comply with safety regulations, improve operational reliability, and provide a safer environment for workers. For any gas welding or cutting setup, flashback arrestors are a vital investment in safety and operational peace of mind.