oday, we are launching an intelligent plasma cutting gun. This cutting gun integrates technology, outstanding performance and humanized design, aiming to provide an cutting experience and efficiency improvement for fields such as metal processing, manufacturing, aerospace and heavy equipment manufacturing, marking the entry of industrial cutting technology into a brand-new intelligent era.

Traditional cutting operations often face challenges such as insufficient precision, complex operation, high energy consumption and high maintenance costs. In response to these industry pain points, the R&D team has devoted all their efforts to creating this intelligent cutting gun. It is not merely a tool, but a complete precision cutting solution.

Core innovation highlights include:

Intelligent and precise control system: Equipped with high-precision sensors and AI algorithms, it can automatically identify the type and thickness of materials and match cutting parameters (current, air pressure, speed) with one click, greatly reducing the reliance on the operator's experience. Even beginners can easily complete the cutting operation, effectively eliminating material waste and rework.

Cutting performance and efficiency: Utilizing advanced plasma generation technology, the cutting speed is increased by up to 30% compared to traditional equipment, resulting in smoother and flatter cuts that require almost no secondary processing. Its powerful penetrating power can easily handle various difficult-to-machine materials such as alloy steel, stainless steel and non-ferrous metals, significantly improving production efficiency.

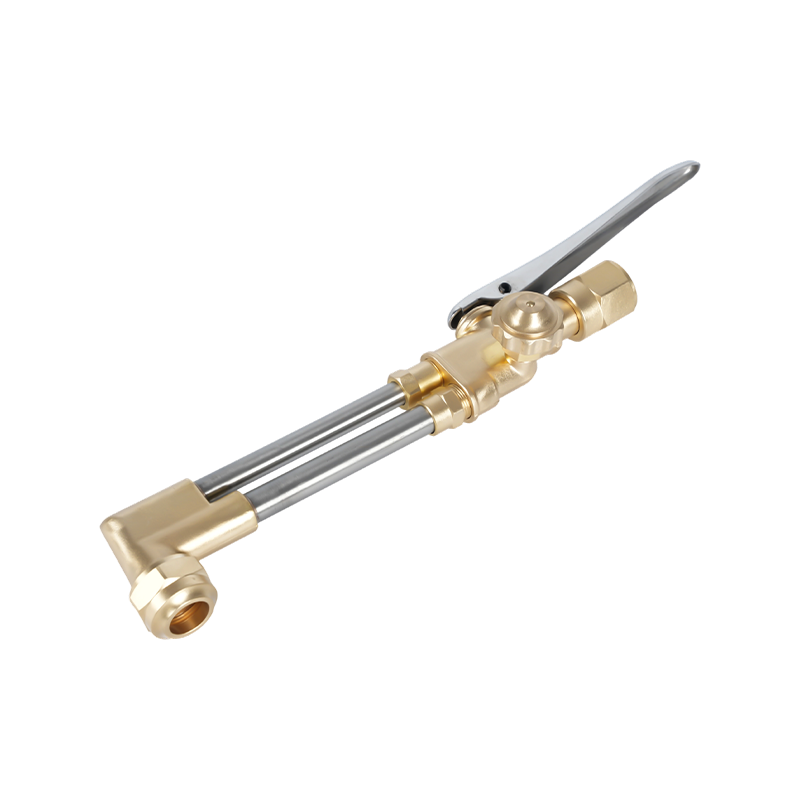

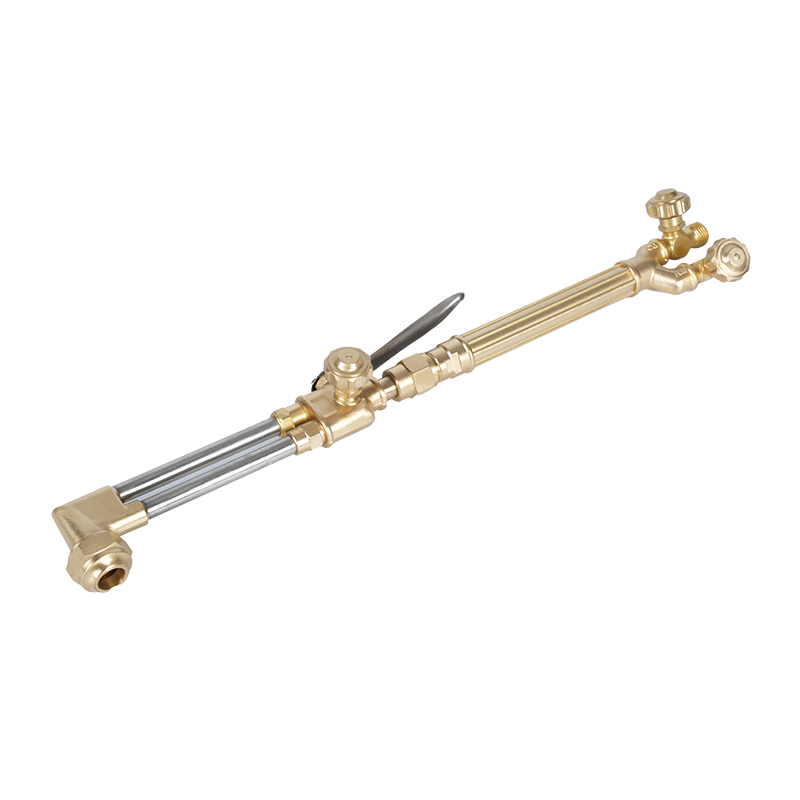

Durability and safety: Key components are made of special ceramic and copper alloy materials and processed through special techniques, featuring wear resistance and high-temperature resistance, with a service life extended by more than 50%. Meanwhile, it is equipped with multiple safety protection mechanisms (such as automatic power-off, high-temperature warning, and anti-backfire design) to comprehensively ensure the safety of operators.

Humanized design and interconnection: The ergonomic lightweight design significantly reduces the operator's fatigue. It supports Internet of Things (IoT) functions and can interact with the factory management system (MES) through wireless connection, achieving real-time monitoring of equipment status, early warning of consumables and analysis of production data, and helping to build a digital intelligent factory.