Choosing the Right Propane Cutting Torch Handle

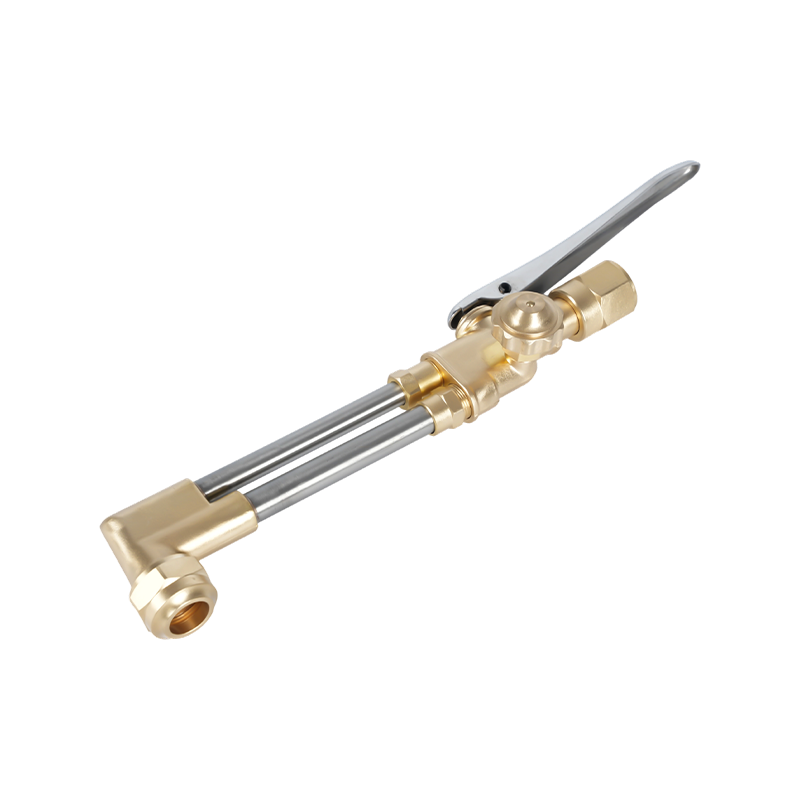

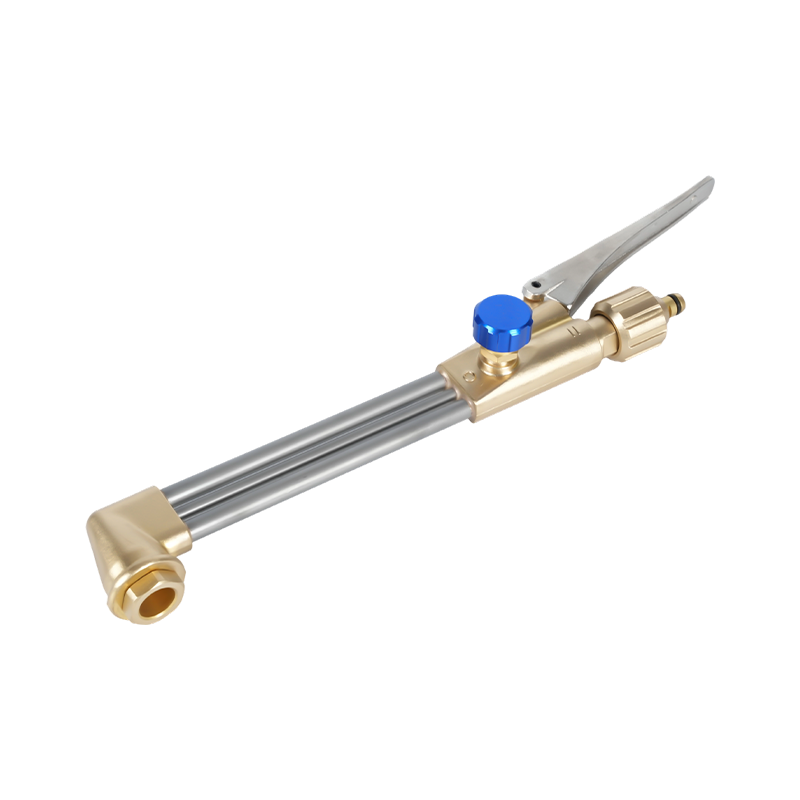

Selecting the Cutting Attachment & Torch Handles is critical for both efficiency and safety in cutting operations. A handle with ergonomic design not only reduces operator fatigue but also allows precise control over the flame. In our experience at Ningbo Dongnuo, handles made from high-quality brass alloys provide superior durability and heat resistance, ensuring a longer service life.

It’s important to match the handle type to the gas flow system. For propane cutting, ensure the handle accommodates high-pressure flow and has reliable valve control. A well-matched handle prevents backflow and ensures consistent flame stability, especially when working on thicker metals.

Ergonomic Features

- Soft-grip design reduces hand strain during prolonged cutting sessions.

- Adjustable trigger tension allows precise control over gas release.

- Integrated swivel joints prevent hose twisting and improve maneuverability.

Propane Cutting Attachments: Material and Performance

Cutting attachments play a pivotal role in the efficiency of propane-based operations. At our factory in Ningbo, we focus on precision forging of brass alloy nozzles and cutting heads. Brass ensures excellent thermal conductivity, resistance to corrosion, and consistent flame shape, which are essential for smooth metal cutting.

Using attachments with properly sized orifices ensures optimal gas mixing and flame intensity. Overly large nozzles can lead to inefficient fuel consumption, while undersized tips may overheat and degrade faster.

Maintenance Tips for Longevity

- Regularly clean the nozzle openings with a soft wire to prevent clogging and flame distortion.

- Inspect handle and attachment threads for wear; replace components showing signs of damage.

- Store torches and attachments in a dry environment to avoid oxidation of metal surfaces.

Optimizing Cutting Performance with Gas Pressure Regulators

Correct gas pressure settings directly influence cutting speed and quality. While our products include highly reliable pressure regulators, understanding the optimal pressure for your material thickness and torch type is crucial. Too low a pressure leads to incomplete cuts, while excessive pressure can damage both torch and material.

Practical Pressure Settings

| Material Thickness |

Recommended Oxygen Pressure (psi) |

Recommended Propane Pressure (psi) |

| 1–5 mm |

15–20 |

5–10 |

| 6–15 mm |

25–35 |

10–15 |

| 16–30 mm |

40–50 |

15–20 |

Innovations in Cutting Torch Accessories

Cutting Attachment & Torch Handles now incorporate features that enhance both safety and operational efficiency. For example, integrated flashback arrestors in our propane cutting attachments prevent dangerous reverse gas flow. Swivel hoses and modular tips allow rapid tool changes without downtime. Personally, I always recommend investing in these safety-enhanced components—they save both time and costly accidents.

Additionally, high-quality flowmeters help monitor gas consumption in real-time, enabling precise adjustments during cutting. At Ningbo Dongnuo, we often advise our customers to combine precision handles with calibrated flowmeters for the most consistent results.