Acetylene Torch Flame Control

Acetylene torches provide a high-temperature flame, ideal for precision cutting and welding. One practical tip I always share with clients is to adjust the flame by first opening the acetylene valve slightly, then slowly introducing oxygen until you achieve a sharp, non-smoking inner cone. This ensures optimal heat concentration and minimizes metal oxidation.

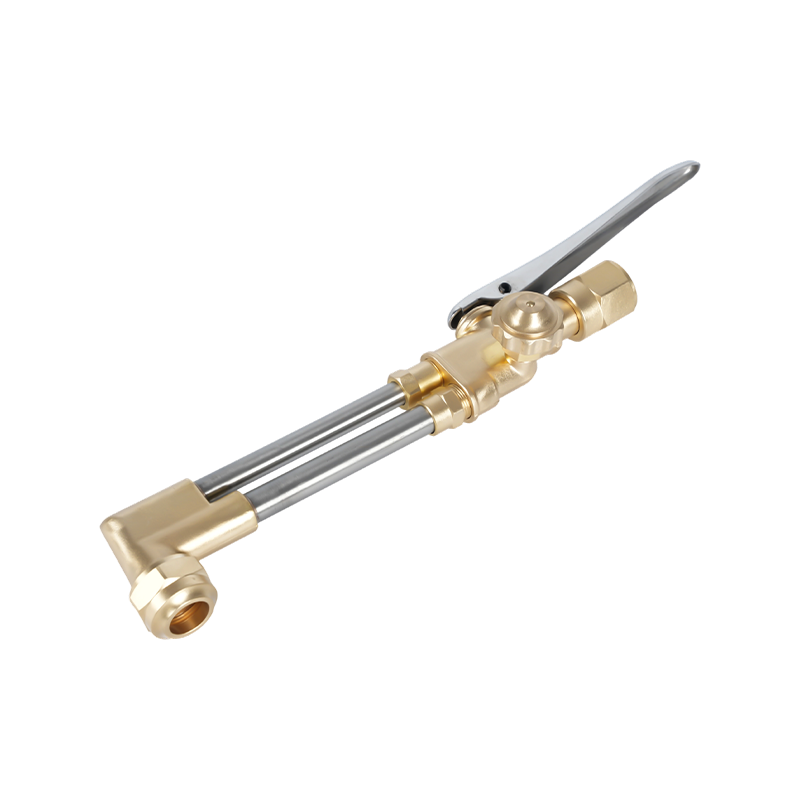

In our workshop at Ningbo Dongnuo, we often demonstrate how small adjustments in acetylene flow can significantly reduce material waste. Using quality components like our precision-cutting guns helps maintain consistent performance, which I find many beginners underestimate.

Propane Cutting Torch Tips and Efficiency

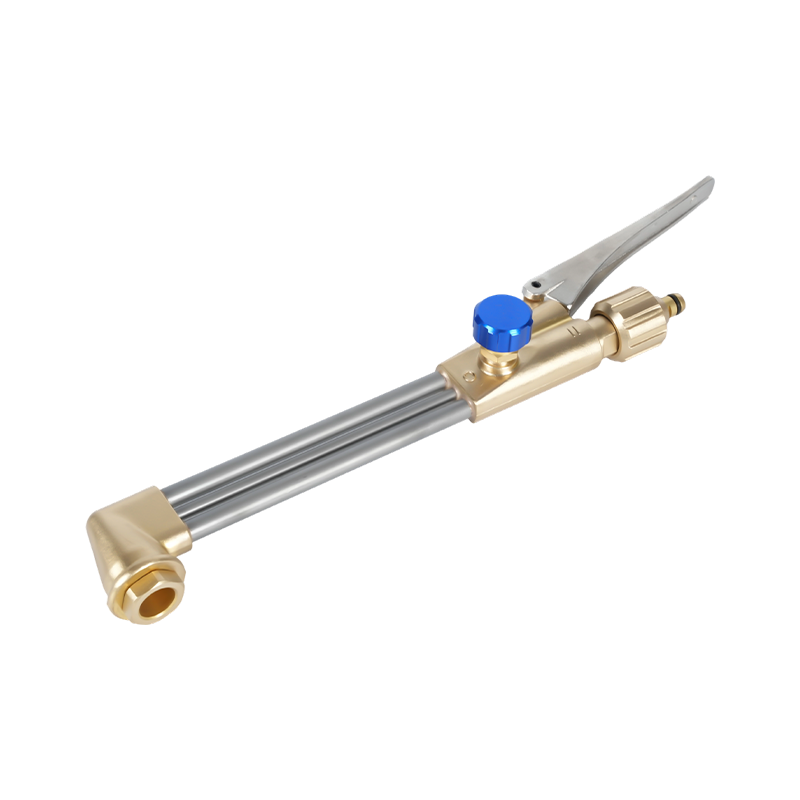

Propane cutting torches are increasingly popular due to fuel availability and cost-effectiveness. Unlike acetylene, propane requires slightly higher oxygen pressure for a clean, deep cut. I usually recommend starting with a 1.2:1 oxygen-to-propane ratio and adjusting according to the metal thickness.

One practical insight I share is that propane torches can overheat tips quickly if used continuously at maximum flame. Rotating the torch tip or pausing briefly can prolong its life, saving replacement costs—something we’ve optimized in our own range of cutting nozzles.

Material-Specific Torch Usage

Different metals require different Acetylene Cutting Torch techniques. For example:

- Carbon steel: Standard acetylene flame, moderate oxygen flow, fast cutting speed to prevent slag build-up.

- Stainless steel: Use slightly lower flame temperature to avoid discoloration; propane torches can be advantageous for controlled heating.

- Aluminum: Preheating with propane before cutting is effective due to aluminum’s high thermal conductivity.

I always emphasize using precision-cutting tools like ours, as the quality of the torch and nozzle directly impacts cut smoothness and operator safety.

Optimizing Cutting Speed and Accuracy

Speed control is crucial for both acetylene and propane cutting. A slower, steady movement often produces cleaner edges, whereas rapid movement can create uneven cuts and excess slag. I personally guide our customers to test their cutting speed on scrap pieces first, which reduces mistakes on expensive materials.

For complex shapes, maintaining a consistent tip-to-metal distance is essential. Our ergonomic torch handles are designed to make this easier, allowing precise control without operator fatigue.

Safety Considerations for Torch Operation

Proper safety measures go beyond wearing gloves and goggles. Flashback arrestors and regulators are vital for preventing accidents caused by reverse gas flow. In our factory, we integrate these safety devices in every system we supply, ensuring both professional and hobby users can work confidently.

Another practical tip is to always purge hoses before ignition. This removes trapped gases that could ignite unexpectedly, a small step that significantly improves safety during cutting operations.

Torch Nozzle Maintenance and Longevity

Nozzle maintenance is often overlooked but critical. Deposits can form inside acetylene and propane nozzles over time, reducing efficiency. I advise regular cleaning with proper wire brushes and checking for cracks or deformation.

| Tip Type |

Recommended Cleaning Interval |

Expected Lifespan |

| Acetylene Cutting Tip |

After 20 hours of use |

6-12 months |

| Propane Cutting Tip |

After 25 hours of use |

8-14 months |

| Heating/Welding Tip |

After 15 hours of use |

6-10 months |

Using high-quality tips from our Dongnuo brand ensures better heat distribution and longer service life, making your investment more efficient over time.